|

|

| |

DESCRIPTION

|

| HYBRID n-COAT is a hybrid coating synthesized of inorganic components as main component and organic components as sub-component with molecular unit reaction. The topcoat and surface hardener with HYBRID n-COAT is an ideal solution for new construction and maintenance projects that require superior protection against abrasion, corrosion, and chemical attack. |

|

| |

n-COAT PRINCIPLES

|

A by-product of cement hydration is calcium hydroxide which is soft and water soluble. Rapid erosion of calcium hydroxide causes surface dusting and leaves microscopic pits and voids in concrete floors. HYBRID n-COAT penetrates into the cementitious substrate and chemically reacts with calcium hydroxide to transform calcium hydroxide into calcium silicate hydrate (CSH) which makes the substrate stronger and more durable.

Also, by penetration and its chemical reaction, HYBRID n-COAT bonds perfectly onto the floor. |

|

| |

|

| |

| |

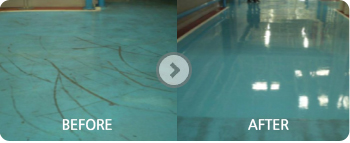

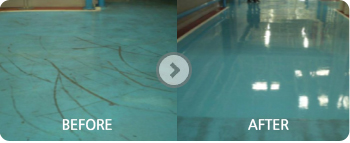

HYBRID n-COAT in Plants

|

| H factory |

P plant |

|

|

Quarterly Repaint

Due to contamination |

Clean for 3 years

without repainting |

|

| Abrasion due to heavy weight materials |

Long lasting

anti-abrasion qualities |

|

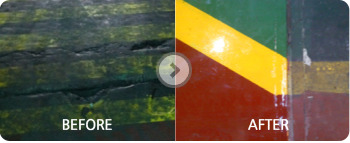

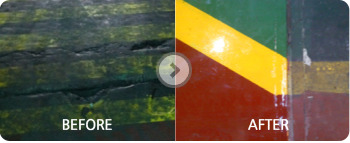

| D factory |

S factory |

|

|

Repainting impossible

Due to delay in production |

Fast drying time enables

1 day application |

|

| Deteriorated due to hot water and chemicals |

Superior thermal resistance,

Chemical resistance |

|

| |

|

|

| |

HYBRID n-COAT in Parking lots

|

| L Apartment |

Parking Lot |

|

|

| Serious abrasion at ramp |

Anti-abrasion and high adhesiveness |

|

| Bump accidents and noise |

Non-slip floor gives silence

and prevents accidents |

|

| Parking Lot |

S Hospita |

|

|

Non-slip floor nonflat due

to manual application |

flat non-slip floor using by

spraying |

|

Light reflection and lack of

elegance |

Matt embossing gives

elegance |

|

| |

|

|

| |

HYBRID n-COAT in Facilities

|

| D Resort |

Training Institute |

|

|

| Risk of fire |

Nonflammable, suitable for

multiuse facilities |

|

| Slippery floor |

Non-slip safe floor |

|

| |

|

| Hospital |

Warehouse |

|

|

Unable to apply epoxy due to

its harmfulness |

Environmentfriendly Certificated product, Sealed construction |

|

| Polishing contamination and crack problems |

Smart polishing,

easy maintanance |

|

| |

|

|

| |

Flooring comparison table

|

| |

HYBRID n-COAT |

Epoxy Lining |

Epoxy-coating |

Urethane flooring |

| Summary |

Inorganic flooing |

Organic flooring |

Organic flooring |

Organic flooring |

Principal

ingredients |

Inorganic binder

mineral pigment |

Bisphenol-A resin

pigment, filler, etc. |

Bisphenol-A resin

pigment, filler, etc. |

Urethane resin

pigment, filler, etc. |

| Strengths |

Nonflammable

(750 ℃)

High durability. Chemical resistant.

Anti-slip. Noise control |

Chemical resistant,

Anti-abrasion |

Thin film

Chemical resistant,

Anti-abrasion |

Outdoor application available

Strong hardness, elasticity |

| Weaknesses |

Higher price than epoxy |

Vulnerable to fire

(creates poisonous fume) |

Vulnerable to fire

(creates poisonous fume)

Weak durability |

Vulnerable to fire

(creates poisonous fume)

Requires special

equipment application defects |

| Eco Friendly |

Eco-friendly. Non-toxic |

Includes TVOC |

Includes TVOC |

Includes TVOC |

| Thickness |

0.3~3mm |

3mm |

3mm |

3mm |

|

| |

| |

Performance comparison table

|

| Performance |

Epoxy |

Urethane |

Surface

hardener |

HYBRID n-COAT |

| Adhesion |

E |

G |

E |

E |

| Abrasion resistance |

G |

P |

E |

E |

| Stain resistance |

G |

P |

G |

E |

| Scratch resistance |

G |

P |

G |

G |

Fire resistance

(Firing, flame spread) |

P |

P |

E |

E |

Appearance

(Leveling, color, roller marking, glossing) |

E |

G |

B |

E |

| Eco-friendly |

B |

B |

E |

G |

| Water vapor permeability |

B |

B |

G |

G |

Chemical resistance

(solvent) |

E |

G |

P |

E |

| Water resistance |

G |

G |

B |

E |

| Acid, Alkali resistance |

G |

G |

B |

E |

| Waterproofing |

E |

E |

P |

E |

| Anti-slip |

P |

P |

E |

G |

Maintenance

(cleaning, repair , durability) |

G |

B |

B |

E |

|

| E : Excellent G : Good P : Plane B : Bad |

| |

Features

|

| ① Superior thermal resistance (Nonflammable) |

|

|

|

| Epoxy Coating |

Solvent-free Epoxy lining |

HYBRID n-COAT |

|

| |

| ② Superior anti-abrasion/surface hardness |

| Test No. |

Epoxy coating |

Solvent-free epoxy lining |

HYBRID n-COAT |

| 1 |

0.3076 |

0.2421 |

0.1926 |

| 2 |

0.2885 |

0.3155 |

0.1869 |

| 3 |

0.3049 |

0.2355 |

0.189 |

| Average |

0.3003 |

0.2644 |

0.1895 |

|

| Anti-abrasion test result(abrasion reduction: g) |

|

|

|

|

|

| |

|

Epoxy Coating |

Solventfree Epoxy lining |

HYBRID n-COAT |

|

| Anti-abrasion Test Condition |

| - H-22, 1,000g, 500Cycles- Three times each |

| |

| ③ Superior water/alkali/acid/chemical resistant |

|

|

|

| Epoxy Coating |

Solvent-free Epoxy lining |

HYBRID n-COAT |

|

|

| Test results |

Surface |

Hardness |

| Epoxy coating |

Color change, crumbling |

weakened |

| Epoxy self-leveling |

Serious yellowing |

weakened |

| HYBRID n-COAT |

No change |

No change |

|

| Testing condition : dipped for 8 hours in boiling water for hardness and fragment check |

|

|

| |

| |

| ④ Fast and easy application |

| |

Applying time(hardening time) |

Curing time |

Total time(ready to walk) |

| Epoxy Lining |

15hrs/one coatingTotal twiceTotal time

30 hours

|

48 hours |

ApproximatelyOne week |

| HYBRID n-COAT |

3hrs/one coatingTotal three times

Total time

9 hours

(70% less time)

|

24 hours

|

Approximately

Two days

|

|

| |

Application Tools

|

|

|

| |

Suitable for both new & old floors

|

|

|